|

|

|

|

It Collates

And it's a |

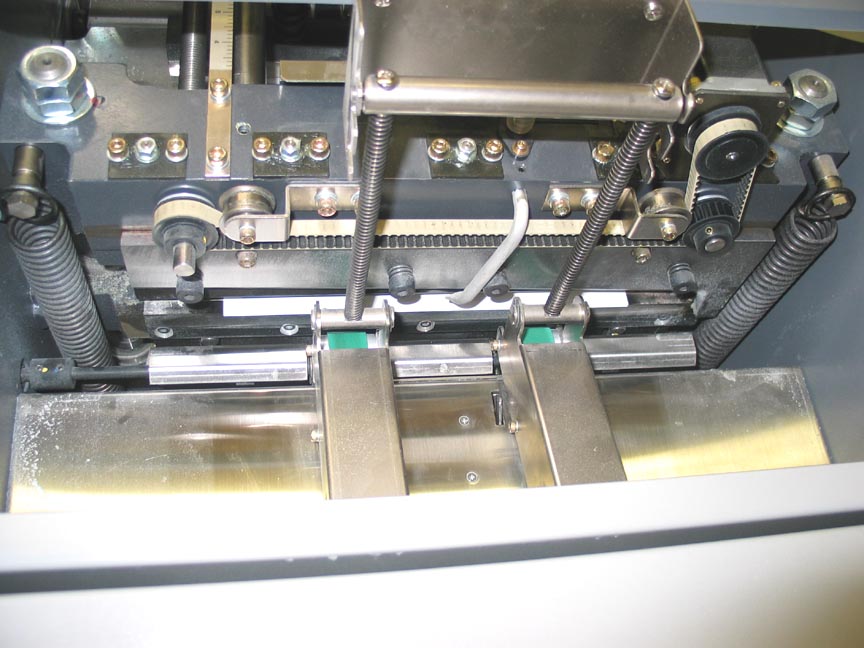

Horizon 30-Bin Vacuum-Fed Bookletmaker / Collator |

|

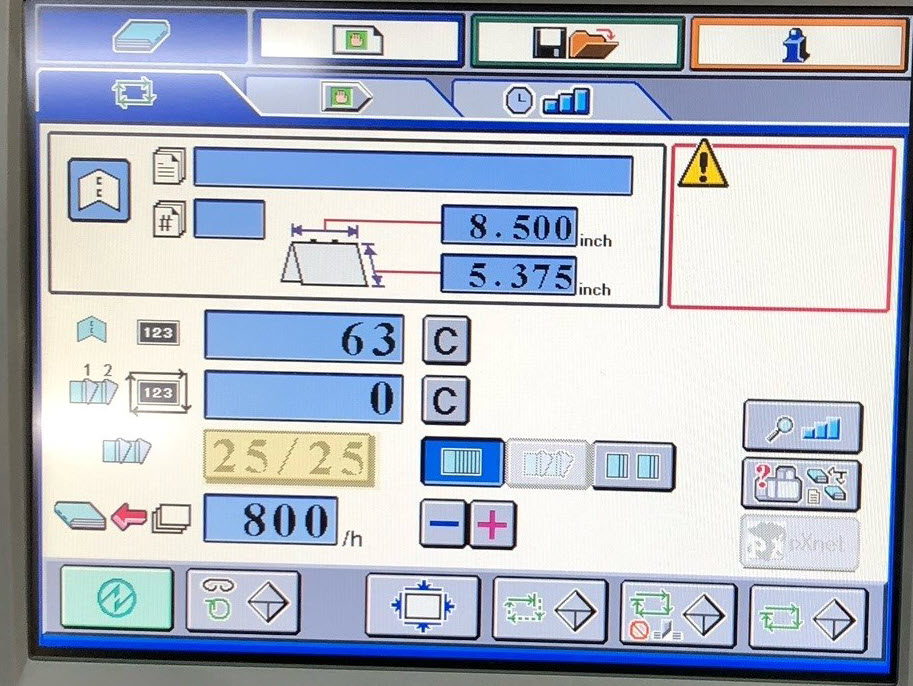

With our brand new Horizon System, we now have the ability to produce Landscape booklets with a maximim sheet size of 24 x 14 flat, folding to 12 x 14 finished. Provides fast, accurate collating of a wide range of jobs, on both coated and uncoated stock from 20# bond to 12 pt. cover stock. From saddle stitched booklets, side stitched manuals or corner stitched reports...to collated flat sheets. It does them all! Saddle stitched booklets in finished sizes from 3½ x 4Ύ up to 14 x 12 (Long Landscape Size Booklets). Booklets with up to 20 sheets are easily produced in one operation, limited only by actual paper thickness and grain direction. Corner, Side or Top stitching of flat sheets from 5½ x 8½ up to 14 x 16Ύ

Collates flat sheets up to 14 x 19Ύ

|

|

4-Plate folder right angle modified for refolding. |

We can score and refold saddle stitched booklets in-line, either parallel or at a right angle to the spine. Half fold or letter fold, up to 4 sheets of 60# offset. Minimum booklet size 5½ x 8½ folded to 4Ό x 5½.

We also fold collated sets without stitch, side stitched, or corner stitched when needed, either half fold or letter fold. This process is limited to 5 sheets of 8½ x 11 of 20# bond. Contact us for details about your project. |

|

Bookletmakers in one form or another have been around for many years. The basic concept is to utilize precut paper, which is then collated, jogged, stapled while still flat, folded then face trimmed to make a finished saddle stitched booklet. Accurate cutting of the sheets will assure a high quality finished job.

|

|

|

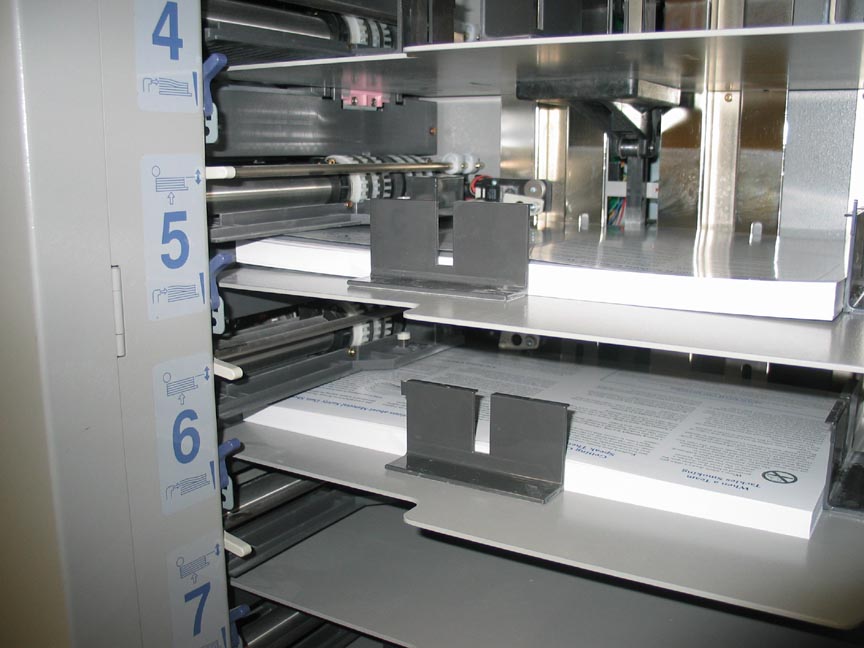

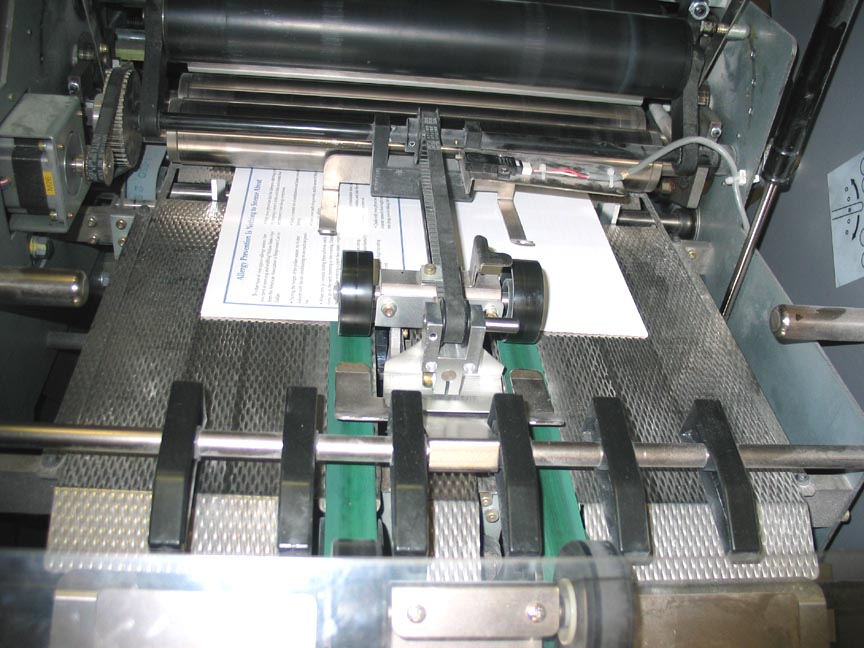

Our state-of-the-art bookletmaker features vacuum-fed bins with extremely accurate sensors capable of detecting blank sheets or double feeds, thus assuring perfect saddle stitched booklets every time. |

|

|

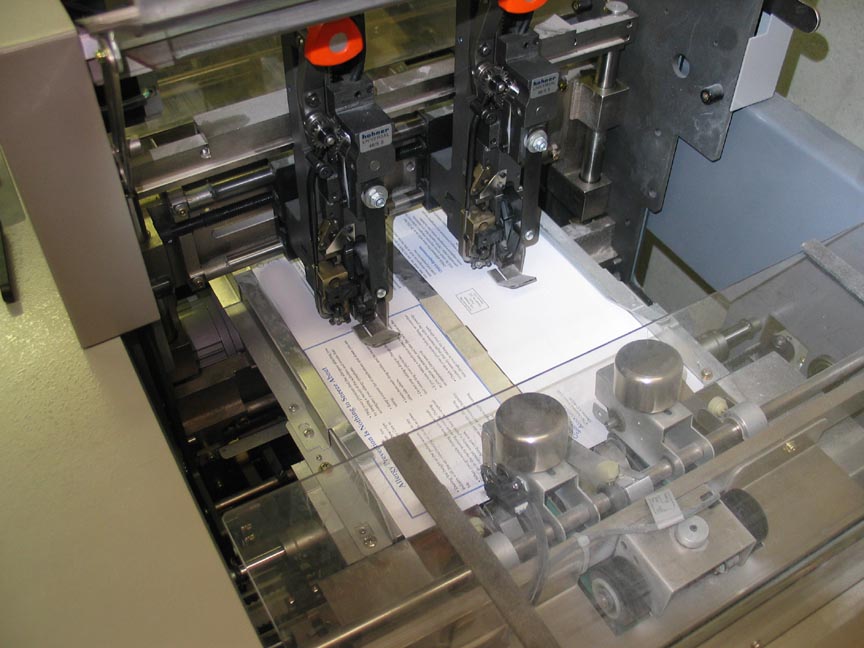

After collating, the sheets accumulate in the stitching section, where they are jogged then stitched while still flat. We use thiner stitcher wire where possible to improve the appearance of the finished booklet. |

|

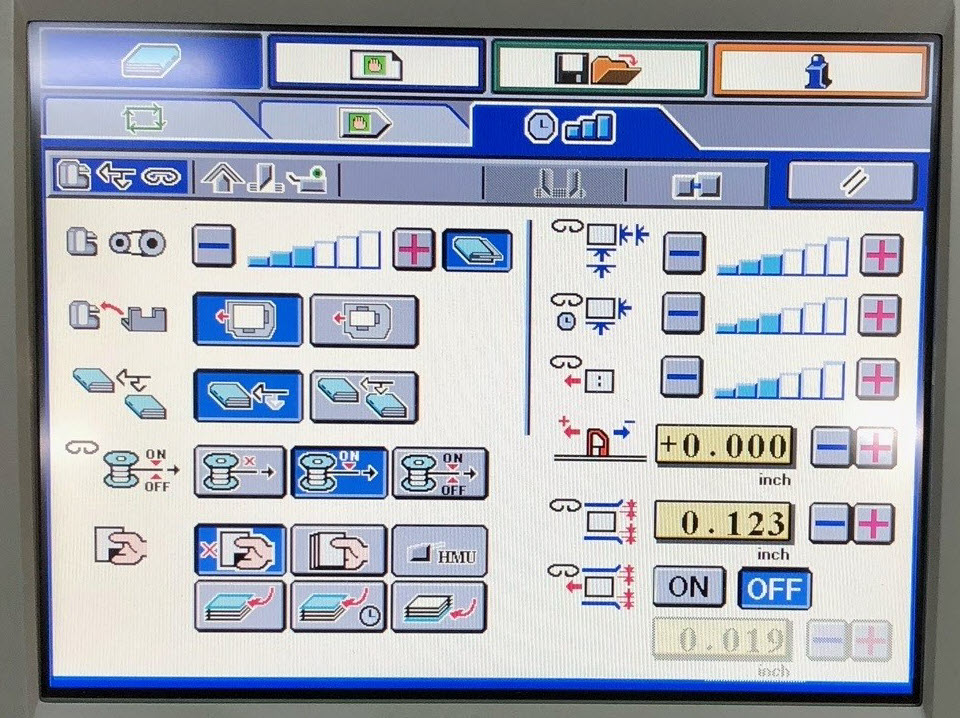

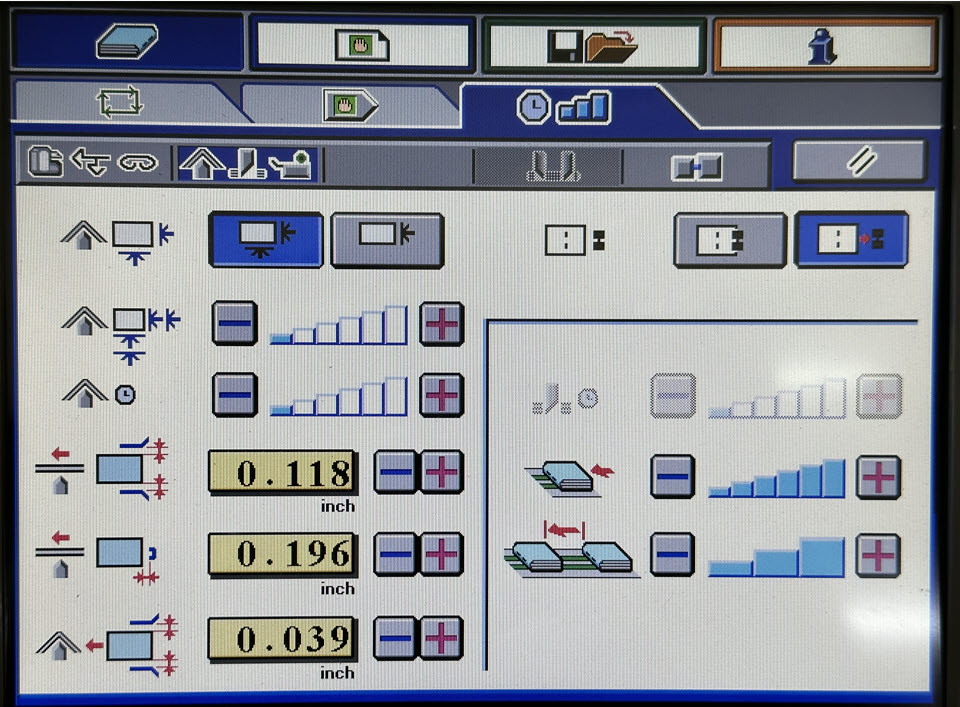

All dimensions for tight jogging and accurate stitching of saddle stitched booklets are quickly and accurately modified from default settings as needed for highly critical jobs. |

|

|

The jogged and stitched booklet is then transported into the folding section where it is aligned squarely then folded between two stainless steel rollers, followed by two hard rubber rollers to further tighten the fold. |

|

All final fold dimensions for saddle stitched booklets are also quickly adjusted for accurate center fold position as well as squareness, using the simple computer screen. |

|

|

|

The saddle stitched and folded booklet is then transported into the trimming section, where it is accurately aligned against a steel stop block, clamped, then face trimmed. |

|

Trimming dimensions of saddle stitched books often need to be fine-tuned to assure a smooth edge and accurate sizing. The final size is quickly changed using the touch screen. |

|